MIL-DTL-3155D(SH)

4.3.1.2 Sampling for examination. A random sample of valves shall be selected from each lot for the

examination specified in 4.4 with conformance based on the sampling requirements of ANSI/ASQ Z1.4, at

inspection level III.

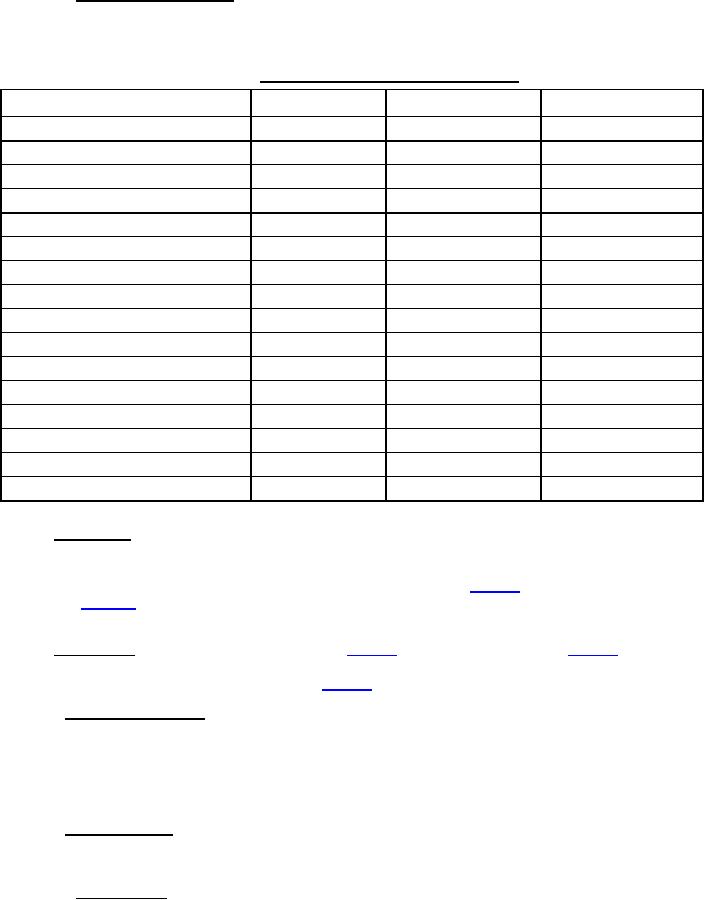

TABLE VI. Qualification and conformance inspections.

Characteristic

Requirement

Qualification

Conformance

Temperature-regulating valve

Thermostat

Materials

Removable parts

Shock

Dimensions and tolerances

Pressure capacity

Valve operation

Valve unit

Thermostat

Bellows

Capillary tubing

Bulbs

Manually operable element

Bulkhead stuffing box

Workmanship

4.4 Examination. Each of the temperature-regulating valves tested in accordance with 4.5 or sampled for

4.3.1.2 shall be examined and measured to verify compliance with the requirements of this specification. Materials

used in the manufacture of valves shall be examined to determine conformance to 3.3. This examination shall

encompass all visual examinations and dimensional requirements specified in table VI. Classifications of defects

are shown in table VII. Noncompliance with any specified requirements or presence of one or more defects

preventing or lessening the maximum efficiency shall constitute cause for rejection.

4.5 Test methods. Test methods shall be as listed in table VI. The requirements listed in table VI shall be

tested in accordance with the applicable tests and test paragraphs listed therein. Results of tests shall be in

accordance with the requirements paragraph listed in table VI or in the test paragraph.

4.5.1 High-impact shock test. Each type of thermostat and the largest size of each model temperature-

regulating valve shall be shock tested in accordance with MIL-S-901 for Grade A, Type A, Class I equipment. The

valve shall be tested in the open position and in the closed position. The test shall be conducted prior to the tests of

4.5.2 through 4.5.5; the correction of damage which may have occurred during shock tests shall not be performed

prior to these tests. Cause for rejection shall be evidence of fragmentation or missile effect of parts, or deformation

of parts that will cause active interference between parts.

4.5.2 Performance tests. Performance tests shall be conducted on one temperature-regulating valve of each

model, size, and type of thermostat(s) as specified in 4.5.2.1 through 4.5.2.4, inclusive, and shall be made with dry

saturated steam at a pressure of not less than 34 psig nor more than 36 psig at the valve inlet.

4.5.2.1 Valve capacity. Valve capacity shall be determined with a 25-psig back pressure at the valve outlet and

with the valve fully open.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business