MIL-PRF-6164G

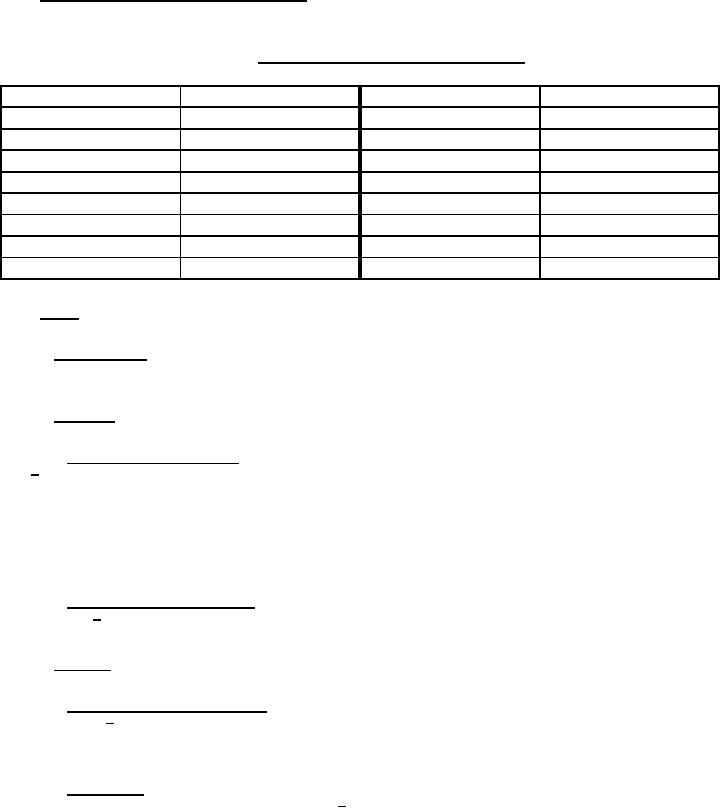

4.5 Requirements cross-reference matrix. Table II provides a cross-reference matrix of the

section 3 requirements tested or verified in the paragraphs below.

TABLE II. Requirements cross-reference matrix

Requirement

Verification

Requirement

Verification

3.1

4.2

3.5.4.2

4.6.3.2

3.3

4.6.1, 4.6.8

3.5.5

4.6.4

3.4.1

4.6.1

3.5.6

4.6.5

3.4.2

4.6.1

3.5.7

4.6.6

3.5.1

4.6.1

3.5.8

4.6.7

3.5.2

4.6.1, 4.6.9

3.6

4.6.1

3.5.3

4.6.2

3.7

4.6.1

3.5.4.1

4.6.3.1

4.6 Tests.

4.6.1 Examination. The valve shall be examined for compliance with the requirements for

materials, dimensions, cap, nut, valve core, markings, and interchangeability.

4.6.2 Leakage.

4.6.2.1 First article leakage test. The valve shall be closed by rotating the nut CW to a torque of

55 +5 inch-pounds. With the valve immersed in water, the maximum rated pressure shall be

applied for 1 minute. The pressure shall then be reduced to 0 psig, increased to 85 psig for 1

minute, and then reduced to 0 psig. There shall be no leakage. Leakage is defined as gas bubbles

forming or rising from the valve or the boss during the last 55 seconds of each 1 minute period of

pressure application (see 6.5).

4.6.2.2 Conformance leakage test. The valve shall be cycled once by opening and closing the

valve to 55 +5 inch-pounds (see 6.6) then subjected to the leakage test in 4.6.2.1.

4.6.3 Cycling.

4.6.3.1 M6164-2 through M6164-5. The valve shall be subjected to 100 cycles of opening and

closing to 55 +5 inch-pounds (see 6.6). After 100 cycles, the valve shall be subjected to the

leakage test in 4.6.2.1.

4.6.3.2 M6164-12. The valve shall be subjected to 500 cycles of testing divided into five 100

cycle sequences of opening and closing to 55 +5 inch-pounds (see 6.6). The first 100 cycle

sequence is performed with the valve pressurized to 8,000 psig and released between cycles. The

second 100 cycle sequence is conducted after the valve is exposed to -65oF for 1 hour at ambient

pressure and then allowed to return to ambient temperature. The third and fifth 100 cycle

sequence shall be performed at ambient temperature and pressure. The fourth 100 cycle sequence

shall be performed after the test valve is exposed to 275oF for 1 hour at ambient pressure and

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business